To achieve this, products need to be designed for manufacture. Often, products need to be designed for a specific identified contracted manufacturer and to suit the resources and abilities that they have at their disposal.

When designing for manufacture we ask several questions including:

Are the components available to the manufacturer?

Are there any restrictions associated with the components?

Can the components be second sourced?

Are the components explicitly specified?

Are tolerances unnecessarily tight?

Is manufacturing information clear, structured and complete?

Are devices easy to program?

Can software be developed or purchased to automate programming, testing, and configuration?

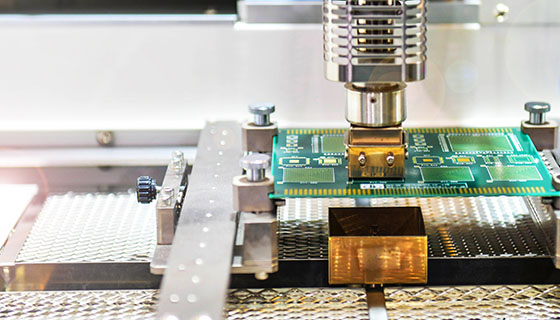

Are PCBs designed for cost effective manufacture, e.g., pick and place, reflow and flying probe testing?

Is the product easy to test?

Are there clear test instructions?

Can cheaper test equipment or jigs be produced to allow for multiple production lines?

Where can automated testing be used or built in test sequences?

Can the device be protected against being copied?

How traceable is the product?

What controls can be put in place?

Often, products need to be designed for a specific identified contracted manufacturer and to suit the resources and abilities that they have at their disposal.

However, there is always a risk that something might go wrong, a component becomes obsolete, a contract manufacturer changes, a new regulation comes into force…

As a business that has been established for over 20 years, you can depend on us to support the manufacturing of your product, system or service in the long term.

One of our customers asked us to develop a high-volume radio-based product and manufacturing was planned to be offshore to reduce costs. The offshore manufacturer had limited radio test equipment but wanted to run multiple production lines. In response we adapted the embedded software of the product and developed a low-cost test setup and procedure that allowed the contract manufacturer to scale up production lines cheaply and efficiently.